Popular Design for Silk Screen Printing Squeegee Polyurethane - Stainless steel emulsion scoop coater – Jiamei

Popular Design for Silk Screen Printing Squeegee Polyurethane - Stainless steel emulsion scoop coater – Jiamei Detail:

Product Specification

It is usually best to get an emulsion scoop coater about 2-3 inches narrower than the inside screen frame width.

| 14 Inch | OD18″ ×20″ screens |

| 16 Inch | OD20″×24″ screens |

| 18 Inch | OD 23″×31″ screens |

| 20 Inch | OD25″×36″ screens |

Easy and comfortable handing.

Easy to cleanup.

Holds more emulsion , Less time refilling & More screens coated,

Chemical-resistant due to its Oxidation surface.

Each side can be used in emulsion coating process with different thickness.

Included with the coater is injection molded ends with a full snap-on dust shield to prevent any particles from mixing in with your emulsion.

Size can be customized according to customer demand

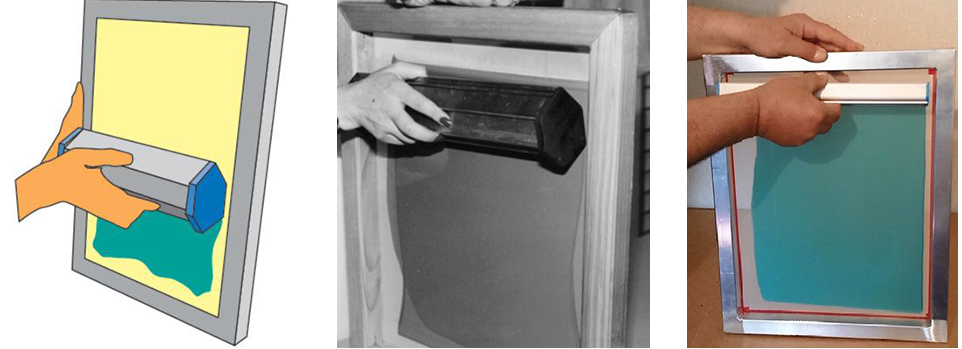

HOW TO USE & CLEAN UP

FILL THE COATER: Under a safe yellow light source, pour emulsion from its container . Allow the emulsion to flow out to an even level. Make sure you have enough to coat in one stroke.

COAT THE SCREEN: Use the rounded edge of a scoop coater to apply an even coat of emulsion in one pass. The coater should be at least two inches shorter that the narrow width of your screen. Apply one coat of emulsion to the printing side, then one coat on the squeegee side. Dry the screen thoroughly.

CLEAN THE COATER: Scrape extra emulsion back into its container. Cover the container. Wash out remaining emulsion with water. Any remaining emulsion that dries in the coater can be very difficult to remove. Store the coater where the edged can’t be nicked.

Product detail pictures:

Related Product Guide:

Fairbanks screen printing shop Nomadic Stars takes a green stance in its work | Local Business | Textile Screen Printing Conveyor Dryer

How Squawk Box Stands In The Way Of Environmentally Sound Entrepreneurship | Flash Dryer Screen Printing

Generally customer-oriented, and it's our ultimate goal for being not only the most trusted, trustable and honest provider, but also the partner for our customers for Popular Design for Silk Screen Printing Squeegee Polyurethane - Stainless steel emulsion scoop coater – Jiamei , The product will supply to all over the world, such as: Spain , Singapore , Belgium , With a state-of-the-art comprehensive marketing feedback system and 300 skilled workers' hard work, our company has developed all kinds of products ranging from high class, medium class to low class. This whole selection of fine products offers our customers different choices. Besides, our company sticks to high quality and reasonable price, and we also offer good OEM services to many famous brands.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!