We analyze from pre-press. Screen printing, is to design drawings by color split out, through the process of plate making, the separate resolution of the color printed separately. So, most of them are a color need to open a screen printing screen. This is more general. Also called spot color screen printing plate. Plate need to open film. The general is to use 45 lines, mesh yarn mesh used 100–135 mesh. In addition there is a CMYK four-color printing, that is, the entire pattern is split into four primary colors, through the principle of overlapping colors, film 55 lines to 65 lines. Mesh mesh about 300 heads. For different patterns, using different color separation methods to achieve screen printing. The higher the fineness, the higher the reduction of the pattern. The more detailed color points. The degree of reduction is also higher. This is prepress. So the more open the board, the higher the cost. The more colors, the higher the cost.

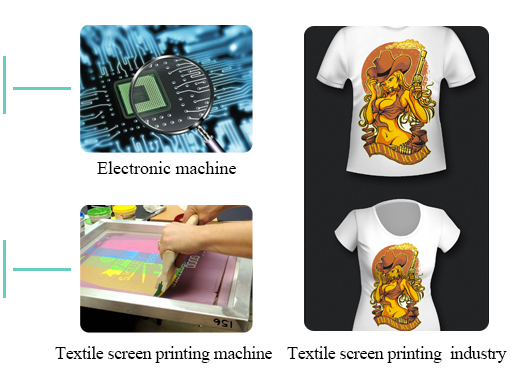

T-shirt silk screen printing

Printed in the process. Printing will be based on different shirt colors, different colors of printing patterns to make the choice of printing materials. Can be pided into several categories.

The first is water slurry printing. The colors you need to print must be color-coded to cover the bottom of a t-shirt. Only in this way can we achieve it. Can take watercolors for reference. On white paper, you can draw any color, but in black paper, watercolor brush on canvas color. Unable to show. By the same token, drawing a deep color on a light-colored garment can also be achieved, but it involves a superimposed, color-changing process. For example, when a blue color is drawn on a yellow garment, it turns green.

The benefits of water paste printing is that it feels soft and breathable. The pigment adheres to the cotton fiber through the cement (resin composition), and the texture of the cloth is transparent. However, the shortcomings of water paste printing, only in light-colored clothes. Wear for a long time, the color of the pattern will have a slight decrease in color.

If you encounter dark fabric how to do? So only cover the color of the cloth at the end of the need for a filling ability of the glue.

Second, mortar printing. Mortar printing can be compared to painting. The printed coating is a glue. This is overcapacity. Because the mortar this material is made of titanium dioxide with polyurethane. It’s like oil painting. Graffiti can be anywhere on any canvas. So glue printing can be adapted to all T-shirt fabrics. No matter what the color of the base coat, it has no effect on the glue printing. Can restore the color of the entire pattern. Since the glue is filled with texture, so it involves the permeability of the. Because the glue printed out there will be a layer of plastic texture. So not suitable for printing a large area of the whole block.

If you want water slurry permeability, but also need to do printing on dark fabrics how to do?

Third, pull print. The color of the cotton cloth is dyed, and the principle of pulling and printing is to destroy the dyeing of the cloth itself, and then dye the color attached to it. After making the printing and printing, there will be no glue gummy feeling, similar to the same water slurry, soft, breathable, but also to do in the dark fabric. The disadvantage is that the cost is relatively high, the loss is relatively large.

Screen printing, but also do a lot of other special printing process, combined with the design, you can make a lot of fun special effects. Such as luminous, reflective, fluorescent, pearl, plate, suede foam, flocking, light color, temperature discoloration, all kinds of laser, colorful reflective, and so on and so forth.

Post time: Aug-13-2019