Hot sale Screen Frame - Hot air Gun – Jiamei

Hot sale Screen Frame - Hot air Gun – Jiamei Detail:

Heat gun with digital display for screen printing

The Heat gun is a valuable ally in the drying of screen printing inks such as Plastisol.

This economical drying system does not replace the use of a screen printing tunnel conveyor or a screen printing flash dryer

Product Usage

Hot Air Gun Operation Instructions

<1> Before use, make sure that it is reliably grounded to prevent static electricity on the tool from damaging the components.

<2> should be adjusted to the appropriate temperature and air flow, according to the shape of the nozzle, the characteristics of the work required to adjust the temperature and air flow of the hot air gun; resistors, capacitors and other tiny components of the de-welding time of about 5 seconds, the general IC de-welding time About 15 seconds, the small BGA de-soldering time is about 30 seconds, and the large BGA de-soldering time is about 50 seconds (eg, when the white light 850B hot air gun uses the A1130 nozzle, the air volume is adjusted to 1st gear and the temperature is adjusted to 3.5 files; when the nozzle is not used, the air volume is adjusted to 4 files. ,The temperature adjusts 4 gears.The digital type ATTEN850D uses the A1130 nozzle when the air volume adjusts 3 gears, the temperature adjusts 350 degrees; When not using the nozzle, the air volume adjusts 4.5 gears, the temperature adjusts 380 degrees).

<3> When the power switch is turned on, the hot air gun should be preheated to a stable temperature before welding can be performed. When using the soldering iron, uniformly heat the unreachable components at 1~2CM above the components. During the process of desoldering, pay attention to protecting the surrounding elements. Device security.

<4> Do not use too much force when installing the nozzle, and do not give a strong impact by tapping the worktable with the soldering iron part to avoid damage to the heating wire and high-temperature glass.

<5> The high temperature operation should be very careful. Do not use the heat gun near flammable gas or flammable objects. Pay attention to personal safety, replace parts, and turn off the power and wait for it to cool. Do not unplug the power plug for a long time.

6> When the work is completed, turn off the power switch. At this time, start the automatic cooling period. Do not unplug the power plug during the cooling period.

Product Specification

|

Adjustable temperature

|

60-650℃

|

|

Rated Voltage

|

220V

|

|

Rated Frequency

|

50/60Hz

|

|

Rated power Input

|

2000W

|

|

Air flow

|

280-480L/Min

|

|

QTY

|

10PCS/CTN

|

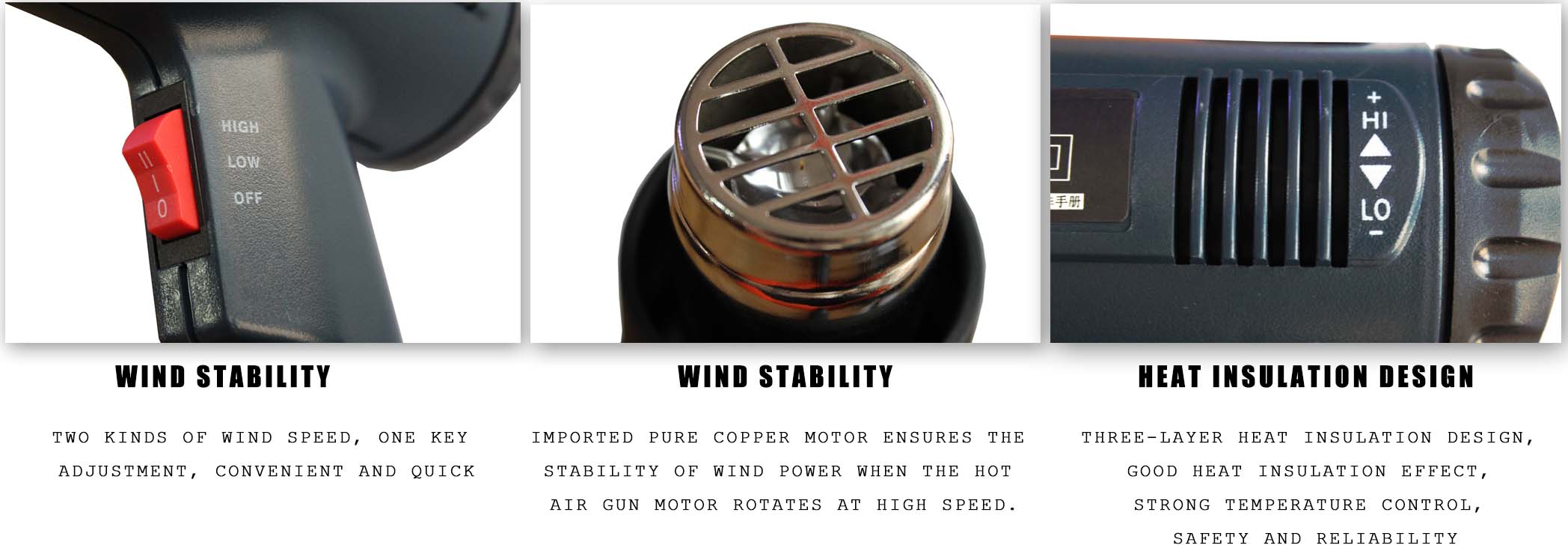

Main Feature

Application

Softening the welding material. ;

Remove the self-adhesive stickers, old wallpaper and decorative;

Lifting rust or nuts and metal screws too tight;

Dissolved the frozen pipes, frozen locks or padlocks, etc.

Processing grease or replacement of the old mill, first softening;

For refrigerator defrost;

Can shrink the PVC film as the protective layer of the packaging;

Can be used in addition to waxing or wax sledge;

Shrinkable polyethylene used connecting metal objects;

Softening the welding material.

Shrinkable polyethylene used connecting metal objects;

Product detail pictures:

Related Product Guide:

Dustpan and Brush squeegees sell out thanks to Mrs Hinch appearance | 100% Polyester Screen Printing

Aurora’s printable textiles on show at SGIA Expo 2018 | Bolting Cloth For Screen Printing

Our commission is to serve our users and clients with best quality and competitive portable digital products for Hot sale Screen Frame - Hot air Gun – Jiamei , The product will supply to all over the world, such as: El Salvador , Algeria , Saudi Arabia , The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!