Competitive Price for Silk Screen Printing Aluminum Handle - A3 DTF PRINTER WITH POWDER SHAKE – Jiamei

Competitive Price for Silk Screen Printing Aluminum Handle - A3 DTF PRINTER WITH POWDER SHAKE – Jiamei Detail:

Dtf printer is called direct to film printer which is a unique printing technology that involves printing designs onto special PET films for transfer onto to a variety of garments (and other substrates). DTF printing machine is a heat transfer process that has the ability to last as long as traditional silkscreen prints. Below, you should know about DTF technology before implementing it in your business.

When printing directly to a textile, your options are limited. DTF Printer gives you much more flexibility, as you can print on a variety of fabrics, including cotton, polyester, rayon, nylon, silk, leather, and more.

DTF printing technology’s strongest selling point would be it ablity to work on almost every type of fabric without the need for pre-treatment, while being able to product sharper and more vibrant colours.

☆Big Color small size DTF printer have 2 sizes for 70cm &30cm. we can use XP600 head or 3200 head. 2 heads model or 1 head model optional for you. It can fit for different working environment.

Product Description

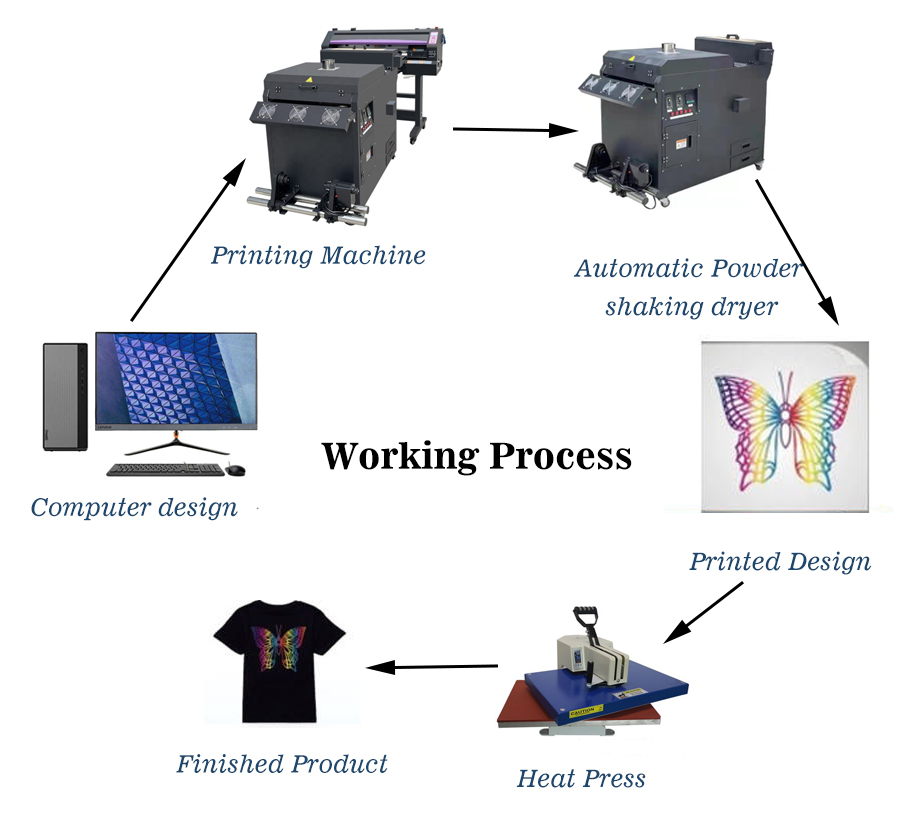

1. Use software draw the pictures , and then use the printer to print the pattern on the PET machine.

2.Sprinkle an appropriate amount of hot melt poweron the printed PET film and shake off the excess hot melt power.

3. Put the PET film on the heat transfer machine and back for 5-7 minutes ,until the hot melt powder melts , take out the PET film.

4. Lay the T shirt flat on the heat transfer amchine and stick the sidesprinkled with hot melt powder on the T shirt for pattern hot samping and the hot stamping takes 15-20 seconds.

Product Specification

| Printhead | EPSON WF-TX800/XP600 | Print speed | 6Pass:3square meter/hour 8Pass:1.5square meter/hour |

| Number of print head | 1 or 2 | Printing accuracy | 360*2400dpl 360*3600dpl 720*2400dpl (6Pass 8Pass) |

| Printer size | 900*470*500mm | Environmental conditions | Temperature:20-28ºC Relative Humidity: 65%-75% |

| Maximum printing width | A3/310mm | Ink type and configuration | textile pigment ink C/M/Y/K/W |

| Weight | 49kg | Working power supply | 220v/110v 50HZ/60HZ |

| Outer packing size | 960*510*540mm | The Ironing temperature | 160-170ºC cold/hot to tear |

| Priting software | 6.1 Maitop/ photoprint | Power | printer:350w powder dryer:2400w |

| Language | Chinese/English | Three heating sections | pre-heater,printing bed heater,rear heater30-65ºC |

| Powder Shaking Machine | |

| Max media | A3 size 30cm width |

| Heating size | 40cm |

| Voltage | 220V/5A |

| Power | 3.4KW |

| Media transmission | NEW belt type |

| Machine Dimension | 85* 65 *60cm |

| Packing size | 95* 70* 70cm/45kgs |

| Take up function | Automatic inductive |

Product Feature

1.Not only can use cloth, it can also transfer onto bag, shoes, notebook, fur and other kinds of fabric material.

2. Automatic white ink stirring system and circuit system, could extent the head working life..

3. All-in-one machine body , printer+ shaker together, it can make sure the machine more stable move easily.

4. We could support you all need spare parts and material. also the air filter. then make sure you get machine can work directly.

5. If you didn’t know how to import the goods, don’t worry, we will help you arrange all shipping issues.

Result Show

Delivery and Packing

Product detail pictures:

Related Product Guide:

Hearing Problems | Headphones, Phone, TV Settings | Flash Dryer Screen Printing

The Quietus | Features | Craft/Work | Printing Squeegees

Our firm sticks to the basic principle of "Quality is the life of your company, and status will be the soul of it" for Competitive Price for Silk Screen Printing Aluminum Handle - A3 DTF PRINTER WITH POWDER SHAKE – Jiamei , The product will supply to all over the world, such as: Birmingham , Armenia , Southampton , We insist on "Quality First, Reputation First and Customer First". We are committed to providing high-quality products and good after-sales services. Up to now, our products have been exported to more than 60 countries and areas around the world, such as America, Australia and Europe. We enjoy a high reputation at home and abroad. Always persisting in the principle of "Credit, Customer and Quality", we expect cooperation with people in all walks of life for mutual benefits.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.