2017 wholesale pricePen Screen Printing Machine - V shape aluminum emulsion scoop coater – Jiamei

2017 wholesale pricePen Screen Printing Machine - V shape aluminum emulsion scoop coater – Jiamei Detail:

Product Specification

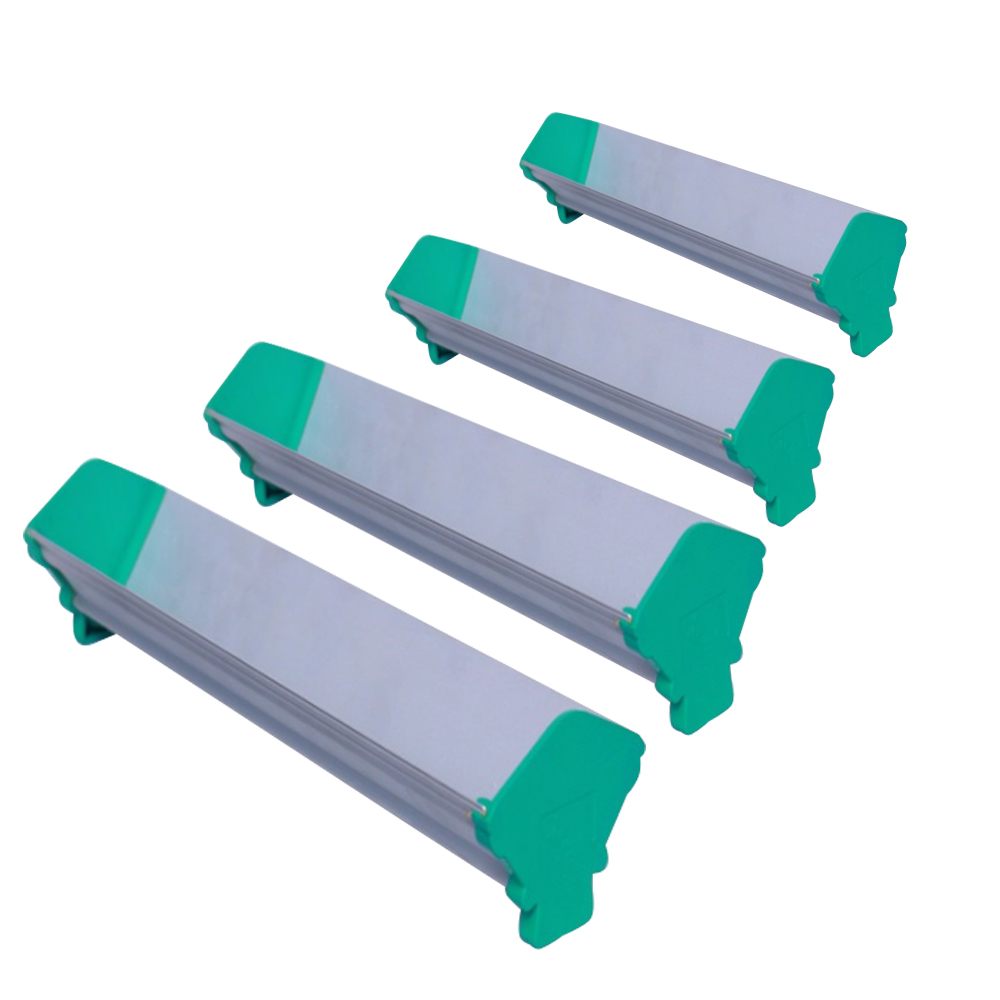

It is usually best to get an emulsion scoop coater about 2-3 inches narrower than the inside screen frame width.

| 14 Inch | OD18″ ×20″ screens |

| 16 Inch | OD20″×24″ screens |

| 18 Inch | OD 23″×31″ screens |

| 20 Inch | OD25″×36″ screens |

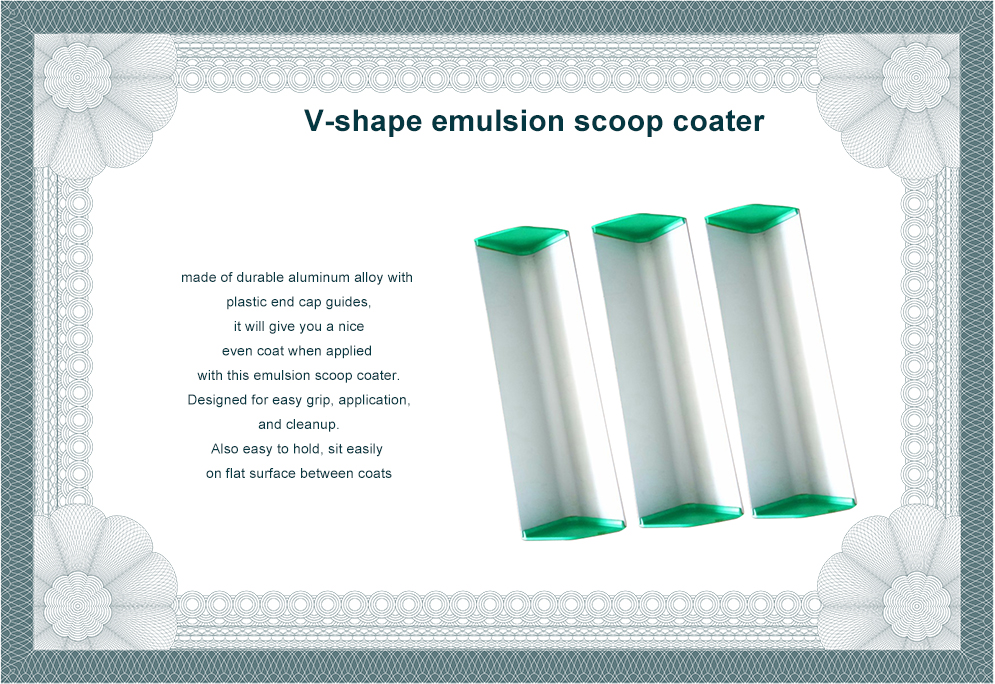

Product Feature Easy and comfortable handing.

Easy and comfortable handing.

Easy to cleanup.

Holds more emulsion , Less time refilling & More screens coated,

Chemical-resistant due to its Oxidation surface.

Each side can be used in emulsion coating process with different thickness.

Included with the coater is injection molded ends with a full snap-on dust shield to prevent any particles from mixing in with your emulsion.

Size can be customized according to customer demand

HOW TO USE & CLEAN UP

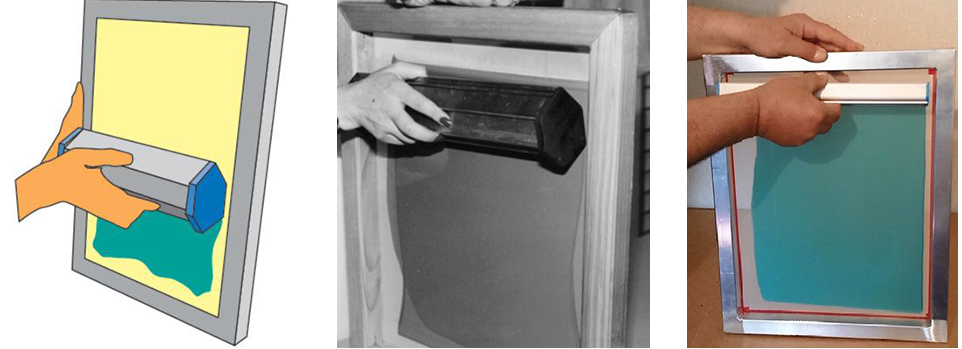

FILL THE COATER: Under a safe yellow light source, pour emulsion from its container . Allow the emulsion to flow out to an even level. Make sure you have enough to coat in one stroke.

COAT THE SCREEN: Use the rounded edge of a scoop coater to apply an even coat of emulsion in one pass. The coater should be at least two inches shorter that the narrow width of your screen. Apply one coat of emulsion to the printing side, then one coat on the squeegee side. Dry the screen thoroughly.

CLEAN THE COATER: Scrape extra emulsion back into its container. Cover the container. Wash out remaining emulsion with water. Any remaining emulsion that dries in the coater can be very difficult to remove. Store the coater where the edged can’t be nicked.

Product detail pictures:

Related Product Guide:

Stahl, HP Collaborate To Offer Sustainable Printing Solutions For Transforming Synthetic Market – Covering the Printing Inks, Coatings and Allied Industries | Textile Screen Printing Conveyor Dryer

Inkjet drupa 2016 | Textile Screen Printing Conveyor Dryer

continue on to further improve, to make sure product top quality in line with market and consumer standard requirements. Our firm has a excellent assurance program have already been established for 2017 wholesale pricePen Screen Printing Machine - V shape aluminum emulsion scoop coater – Jiamei , The product will supply to all over the world, such as: Sacramento , Swaziland , Zimbabwe , Look forward to the future, we'll focus more on the brand building and promotion . And in the process of our brand global strategic layout we welcome more and more partners join us, work together with us based on mutual benefit. Let's develop market by fully utilizing our in depth advantages and strive for building.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!